In an era where semiconductor packaging and surface mount technology (SMT) are continuously evolving towards greater precision and miniaturization, the design and manufacturing of supporting carrier tapes face unprecedented challenges. As a leading provider of carrier tape solutions in the industry, Sinho has always been guided by customer needs, committed to overcoming technical hurdles and driving technological innovation. In June of this year, leveraging its profound technical expertise and innovative spirit, Sinho's R&D team successfully customized and designed two specialized carrier tapes for ultra-thin chips, once again demonstrating the company's outstanding capabilities in the field of precision carrier tape manufacturing.

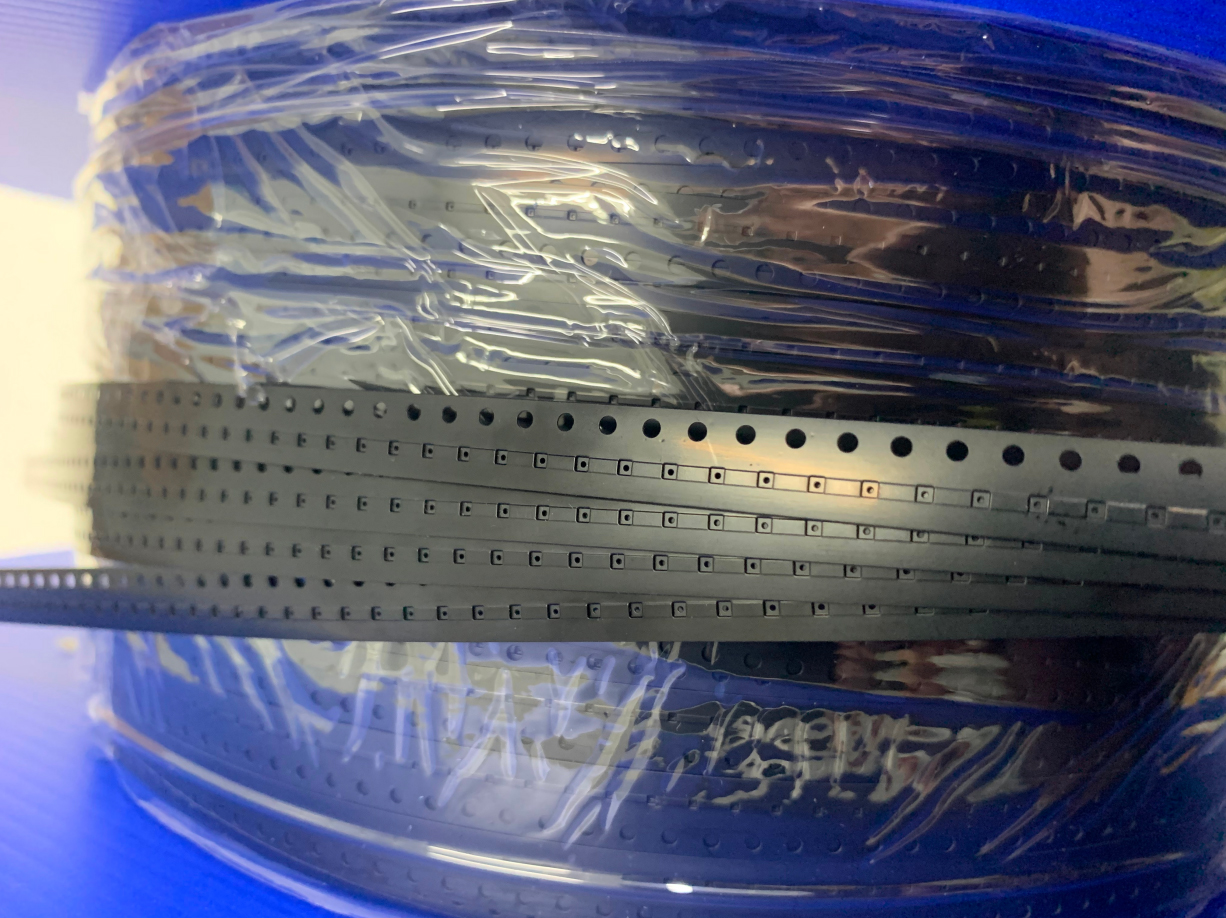

The two custom carrier tapes developed this time are designed for chips with dimensions of 0.50mm x 0.50mm x 0.25mm and 1mm x 1mm x 0.25mm respectively. Such tiny chips require equally delicate accommodation structures in the carrier tapes. The design of the minuscule pockets is particularly challenging. These pockets not only need to precisely fit the chip dimensions to ensure the chips are firmly held in place but also have to meet strict requirements during the production process. Considering these demands, our team ingeniously designed the pocket holes of the two carrier tapes to be 0.3mm and 0.5mm respectively. This was no easy feat, as it demanded meticulous calculations, advanced design software, and in - depth knowledge of material properties to achieve the perfect balance between pocket functionality and structural integrity.

To further enhance the stability of the chips, we introduced a unique design feature - a 0.02mm raised crossbar. This seemingly simple addition plays a crucial role in securing the chips. It effectively prevents the chips from rolling to one side or flipping over completely during transportation and handling. More importantly, it solves the common problem of chips sticking to the cover tape during SMT processing, thus ensuring a smoother and more efficient production process for our customers.

Behind these innovative designs is the unwavering dedication of Sinho's production team. They invested a significant amount of time and effort in the development of the production tools for these two carrier tapes. Through continuous trial - and - error, process optimization, and strict quality control, they ensured that the pockets were well - formed and completely free of burrs. Each carrier tape that rolled off the production line underwent rigorous inspection to meet the highest quality standards.

The successful development of these two custom carrier tapes not only represents a major technological achievement for Sinho but also provides our customers with high - quality products that better meet their specific needs. It is a testament to our commitment to providing innovative, reliable, and customized solutions in the highly competitive semiconductor packaging and SMT industry. As we move forward, Sinho will continue to invest in research and development, keeping pace with the latest industry trends, and striving to create more advanced carrier tape products that drive the development of the entire industry.

Post time: Jun-23-2025